Woodworker's Journal 2004 Spring, страница 48

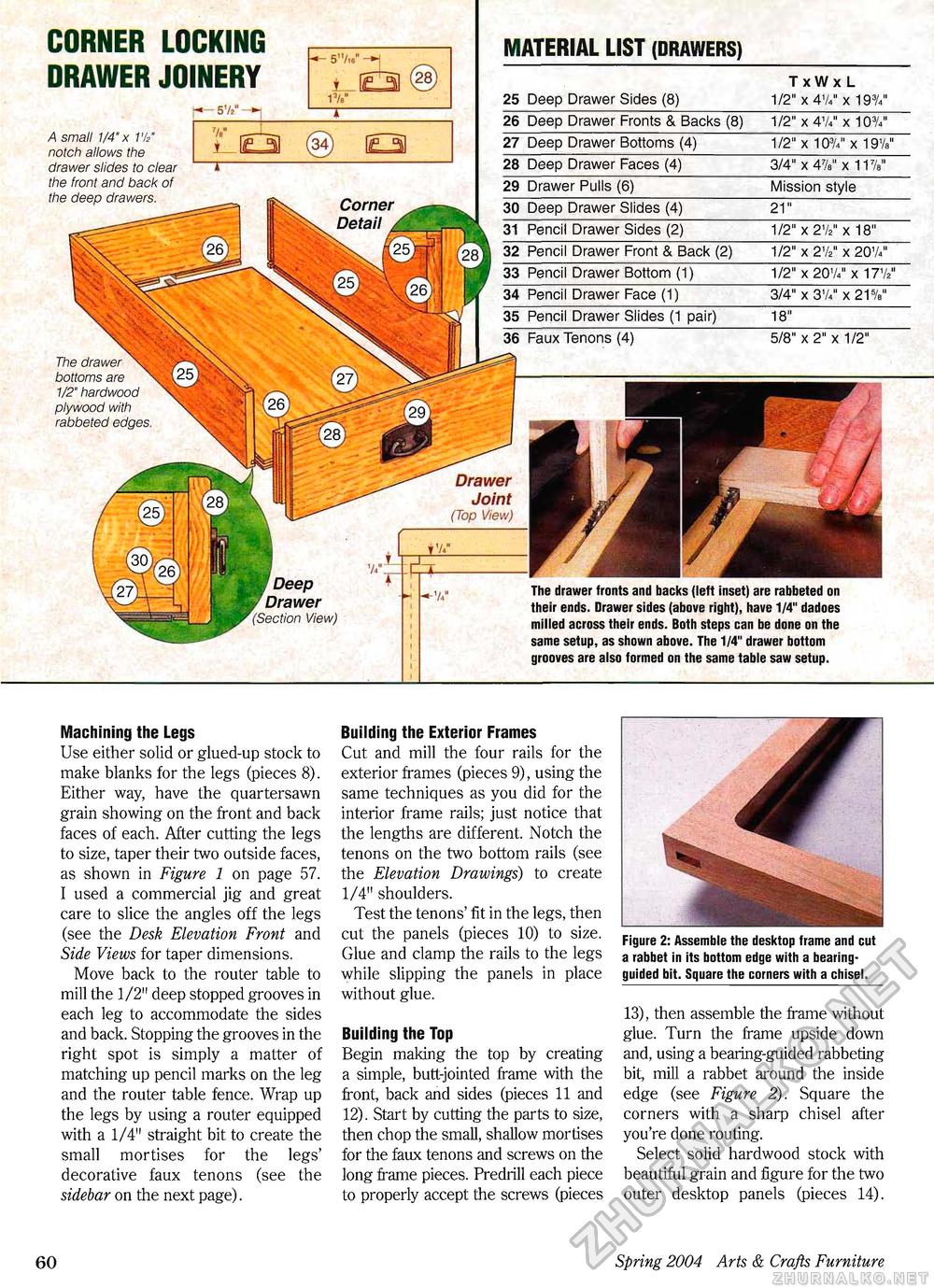

±L Ql @ 1Q 5"/h" -H i Q(§) 17a" MATERIAL LIST (DRAWERS)_ TxWxL 25 Deep Drawer Sides (8) 1/2" x 4V-" x 19%" 26 Deep Drawer Fronts & Backs (8) 1/2" x VU" x 10%" 27 Deep Drawer Bottoms (4) 1/2" x 10%" x 19Va" 28 Deep Drawer Faces (4) 3/4" x 47a" x 11%" 29 Drawer Pulls (6) Mission style 30 Deep Drawer Slides (4) 2T 31 Pencil Drawer Sides (2) 1/2" x 272" x 18" 32 Pencil Drawer Front & Back (2) 1/2" x 272" x 2074" 33 Pencil Drawer Bottom (1) 1/2" x 2074" x 1772" 34 Pencil Drawer Face (1) 3/4" x 374M x 21%" 35 Pencil Drawer Slides (1 pair) 18" 36 Faux Tenons (4) 5/8" x 2" x 1/2" Deep Drawer (Section View) The drawer fronts and backs (left inset) are rabbeted on their ends. Drawer sides (above right), have 1/4" dadoes milled across their ends. Both steps can be done on the same setup, as shown above. The 1/4" drawer bottom grooves are also formed on the same table saw setup. CORNER LOCKING DRAWER JOINERY Drawer Joint (Top View) The drawer bottoms are 1/2" hardwood plywood with rabbeted edges A small 1/4'x Vk" notch allows the drawer slides to clear the front and back of the deep drawers. Machining the Legs Use either solid or glued-up stock to make blanks for the legs (pieces 8). Either way, have the quartersawn grain showing on the front and back faces of each. After cutting the legs to size, taper their two outside faces, as shown in Figure 1 on page 57. I used a commercial jig and great care to slice the angles off the legs (see the Desk Elevation Front and Side Views for taper dimensions. Move back to the router table to mill the 1/2" deep stopped grooves in each leg to accommodate the sides and back. Stopping the grooves in the right spot is simply a matter of matching up pencil marks on the leg and the router table fence. Wrap up the legs by using a router equipped with a 1/4" straight bit to create the small mortises for the legs' decorative faux tenons (see the sidebar on the next page). Building the Exterior Frames Cut and mill the four rails for the exterior frames (pieces 9), using the same techniques as you did for the interior frame rails; just notice that the lengths are different. Notch the tenons on the two bottom rails (see the Elevation Drawings) to create 1/4" shoulders. Test the tenons' fit in the legs, then cut the panels (pieces 10) to size. Glue and clamp the rails to the legs while slipping the panels in place without glue. Building the Top Begin making the top by creating a simple, butt-jointed frame with the front, back and sides (pieces 11 and 12). Start by cutting the parts to size, then chop the small, shallow mortises for the faux tenons and screws on the long frame pieces. Predrill each piece to properly accept the screws (pieces Figure 2: Assemble the desktop frame and cut a rabbet in its bottom edge with a bearing-guided bit. Square the corners with a chisel. 13), then assemble the frame without glue. Turn the frame upside down and, using a bearing-guided rabbeting bit, mill a rabbet around the inside edge (see Figure 2). Square the corners with a sharp chisel after you're done routing. Select solid hardwood stock with beautiful grain and figure for the two outer desktop panels (pieces 14). 10 Spring 2004 Arts & Crafts Furniture |